Gregory Rybak wanted to come to Canada because he believed in the Canadian dream - a better and brighter future for his family and endless possibilities.

Gregory Rybak wanted to come to Canada because he believed in the Canadian dream - a better and brighter future for his family and endless possibilities.

He was right.

Today he owns and operates MCM, a full-service custom manufacturer specializing in the integrated development, manufacture and construction of institutional, commercial and retail, corporate, museum and residential environments.

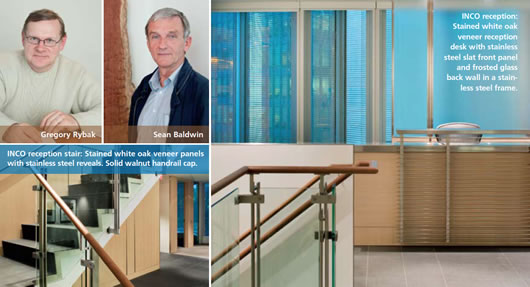

Along with minority partner Sean Baldwin, the company is a leader in custom millwork and fabrication and has established a reputation for craftsmanship, flexibility and completing complex and high profile projects on tight deadlines. In other words, if you need something special, this is the place to go. Their work ranges from individual architectural elements and components, to complex fixtures for retail, complete corporate interiors, and small custom production runs to full project management and construction.

Established in Toronto in 1988 as a privately owned and operated firm, MCM has worked with leading architects, designers and corporations to help them realize and develop their custom environments. MCM’s client list reads like a Who’s Who of high-profile companies and institutions, including: the Royal Ontario Museum, the Art Gallery of Ontario, University of Guelph, Calvin Klein, Saatchi & Saatchi, Museum of Inuit Art, Oxford Properties (Yorkdale Mall), Vale/Inco Corporation, Gardiner Museum of Ceramics, Roots Canada, Hugo Boss, Stratford Festival, Royal Conservatory of Music, Ontario Legislature and many, many more.

And many, including Roots Canada, have been repeat customers, which speaks to MCM’s determination to continually exceed clients’ needs and expectations with quality, craftsmanship and ingenuity. MCM uses a fully integrated approach to customized solutions, which means it can tackle any job, no matter how complex. Every job, big or small, is managed by a dedicated development team, which ‘choreographs’ every aspect from start to finish.

Early experience

Rybak grew up in Poland where his father operated a small woodshop. He worked at the shop after school and also got involved in marketing and selling the products. That’s how he learned the trade and earned valuable experience in all the other aspects involved in running a business.

He graduated from Warsaw University with an engineering degree. It didn’t take Rybak long to realize that Poland, in those days, was not a place to grow a business and he decided to come to Canada with his wife Teresa and their children. His brother had already made his move and was living in New York, but Rybak liked Canada better and decided to go to the Ottawa area because his wife’s uncle was already there. They had to go to Toronto to pick up some belongings, which were sent there by mistake, when Rybak’s uncle told him about a job at a local woodworking shop. It was an easy job given his expertise and knowledge and he spent the first year in Canada working and going to school at night to learn English. There were a few more jobs and their first apartment and after a couple of years Rybak was ready to partner up in his own business, which grew quickly. His timing was perfect and the company secured a major project with a large and growing retailer. They built store fixtures and entire stores and business was growing at a rapid pace.

Then, after a bad break with his partner, Rybak found himself out of a job.

It was a difficult time and he had to start over. He bought an old pickup truck and $5,000 worth of tools and started working as a freelance contractor. After a while one of his former clients called and hired him to do some of the work he had been doing for them before. It was a perfect match and growth and expansion provided the stability and steady work he needed to grow his own shop and also afforded him the flexibility to look at other opportunities.

“We always said yes and then figured out a way to do it,” Rybak says with a smile.

In 2001, he teamed up with Sean Baldwin, who he met a few years earlier, and they continued to grow the business.

Today, MCM operates out of several buildings on Bertal Road and Industry Street in Toronto. With some 140 employees and more than 90,000 sq. ft. of manufacturing space, the company boasts dedicated wood shops, a metal shop and finishing systems as well as a veneering plant. In short everything one would expect to find in a full-service manufacturer.

MCM can build to plan, develop plans and build to customer requirements. From small individual jobs to large projects requiring CAD there really is no limit to what they can do. They have the know-how, the experience, the equipment and the people to tackle any challenge.

Rybak says they also have a large pool of qualified subcontractors for specialized services and site work and more than 20 people provide administrative, CAD and engineering support services to the company.

“We do many unique projects and we use the latest technology as well as traditional skills to deliver the highest quality to our clients,” Rybak says. The metal shop produces everything from top quality architectural components to fully integrated metal and wood pieces.

In addition, Rybak is constantly looking for something new and trying new ideas. One recent example, a large, live-edge table he designed and built for their lunchroom. Built from an old log with beautiful, inset steel legs it’s an impressive-looking and very decorative piece.

“I built just one for our lunchroom, but by now we have made about 25 more for people who saw it and wanted one,” Rybak says with the smile of a man who gets great pleasure from what he does.

From beautiful desks, some appearing to just float in mid-air, to ornate and traditional store fixtures and large museum display cases, MCM’s expertise is to use whatever material required in innovative ways to complete a job with style.

The company is also investing in green technology. From solar panels on the roofs, to the new dust collection system that adapts to usage, MCM is not sitting still. It’s good business and good for business. They are also retrofitting the plant to be more energy efficient and constantly improving the utilization of the 50-ton waste stream created every month.

Rybak and Baldwin are also trying to hire as many young people as they can and they regularly open their business to students from OCAD (Ontario College of Art and Design) and Sheridan (College) for tours.

And despite of all his success, Rybak says he is still learning something new every day. “I enjoy looking at things and figuring out how they were built, how it’s made and how I would do it,” he says.

For Rybak this is not just a business.

Of course he has to work and earn money, but it’s also about quality products and having a good time. “I really enjoy this work and looking at what other people are doing,” he says. “You can never really stop, there is always something new and exciting and we always look for the next thing, the next innovation that we can use for another project.”

MCM by the numbers:

The metal shop has CNCs, laser welding and saws, CNC banding machines and a full complement of other welding equipment.

• FSC Certified

• 90,000 sq. ft.

• 140 employees,

• 2 CNC routers (Biesse, Selco)

• 5 routers (Biesse)

• 1 router (Shoda, three routers and three saws)

• 1 moulder (Weinig)

• 5 saws (Altendorf)

• 2 edgebanders (Holz-Her and Brandt)

• 2 veneering presses (iTal and OTT)

• 2 veneer machines (Josting ZFS 2800 doubleknife guillotine and Kuper FL Innovation gluing machine)

• Stitchers, sanders as well as dozens of other smaller tools.

The metal shop has CNCs, laser welding and saws, CNC banding machines and a full complement of other welding equipment.