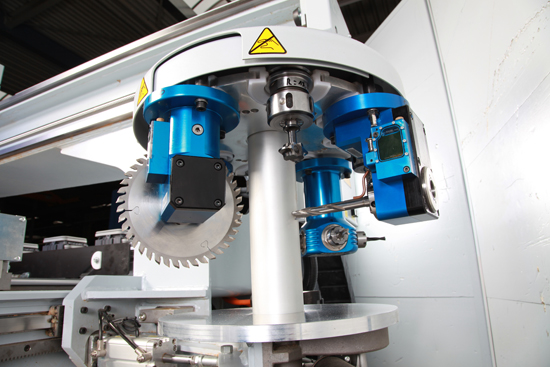

Aggregates in a tool changer

EQUIPPING YOUR BUSINESS FOR SUCCESS

In this issue I would like to talk about adding aggregates to your existing CNC machining center. These aggregates are also referred to as angle heads or angled milling attachments for those of us that come from metal industry.

What is an aggregate for a CNC machining center and what can it do for you? In essence an aggregate is a specially designed tool holder that allows you to extend the capabilities of your CNC machining center. Most aggregates can be stored in the tool changer of your machine, and connect to the main spindle of the router with an SK or HSK interface, just like a regular tool.

There are two main reasons to add aggregates to your machine:

1) to change the direction from which the tool approaches the work piece, i.e. for lock cases and hinge plates.

2) to add a new functionality like drilling square holes, cutting with an oscillating knife or drilling 144 holes at the same time.

Typically, router spindles are mounted at right angles to the machine table. Aggregates are special holders, which allow the operator to mount, orient and use cutting tools like router bits and saw blades at angles other than when mounted directly into the main spindle with a regular tool holder. The angle of the aggregate tool can be fixed for common applications like a 3-degree pilot hole for door hinges, or can be variable for ultimate flexibility. This allows you to come at the work piece from virtually any direction.

The tool mounted in an aggregate is driven through a series of gears, which allows you to run a saw blade vertically to trim window components to length, or run a router bit horizontally to route out hinge pockets on the back edge of a passage door.

Most entry-level routers do not have any aggregate heads included, although most of them can be retrofitted down the road. To be added later on, the aggregate head usually requires an interface component on the main spindle, called a torque support or a C-axis (the 4th axis). To use an aggregate on your machine, you need to ensure that the aggregate is fixed and cannot twist. Therefore aggregates are equipped with an anti-rotation pin, which prevents it from spinning around like any other tool in the router spindle. This anti-rotation pin holds the body of the aggregate in the correct position, while the spindle portion turns at the desired RPM and drives the tool.

The addition of a C-axis is not necessarily required for an aggregate to work on your machine, but it greatly increases the flexibility and makes working with an aggregate much more user friendly. With a C-axis any manual set-up of the required angles is eliminated, which eliminates costly operator errors and makes for a much more fluent operation.

There are two different types of C-axis, a positioning- and an interpolating C-axis. The difference be- tween the two is that a positioning C-axis adjusts the angle of the aggregate before the cutting process and keeps the angle throughout the process. The aggregate will still move left/ right and up/ down relative to the work piece, but the angle of the aggregate relative to the main spindle remains fixed. This type of C-axis is most common on entry-level machines and addresses most, if not all requirements found in a millwork shop.

The interpolating C-axis adjusts the angle of the tool before and throughout the cutting process (while the tool is inside the material). An example for use of the interpolating C-axis would be an aggregate with a blow-off nozzle, where the blow-off nozzle needs to points directly at the edge while it is rotating all the way around a part.

Sawing aggregate

Now that we know what an aggregate is, what would I use such a unit for?

General cabinet work typically does not require an aggregate, but if you could take on additional jobs, like hinging interior doors, the angle head can significantly expand the capabilities of your CNC machining center.

Let’s have a look at a few applications that can involve an aggregate:

PROCESSING OF PASSAGE DOORS

One of the classic applications for aggregates is horizontal routing, e.g. the cutting of a lock case for a door and recessing hinge plates.

MITRE CUTS ON THE EDGE OF A PANEL WITH A SAW BLADE AGGREGATE

The A-axis of the aggregate is ad- justed manually, to - for example - 45 degrees. Result is a perfect mitre cut. By rotating the unit 180 degrees and cutting a slot into the 45-degree edge, we can then add a groove for lamellos.

CUTTING SOLID WOOD COMPONENTS TO LENGTH

In window and door manufacturing you typically load squared solid wood components (S4S) on the router for processing. As part of the machining program a saw blade aggregate can trim these components to the exact length required for later assembly, and a saw blade can handle solid wood up to 3-4” thick.

FLOATING HEAD TO TRACE PROFILES EXACTLY OR TO DO EDGE GROOVING

Thickness tolerances in particle or MDF boards can be worked around with a floating aggregate head. The ring of the floating bell glides and references of the surface, making sure the edge groove is exactly at 8mm from the top of the board.

MACHINE CURVED MOULDINGS WITH A MOULDER AGGREGATE

Making curved mouldings with a moulding aggregate is a great way to save time in the machining process. The aggregate has the right profile knife insert and will follow the middle line of the moulding, with the interpolating C-axis turning the aggregate.

These examples show just a few possibilities of what an aggregate can do for your production. Sometimes the aggregate just makes the process simpler and saves you time, but in other cases the aggregate opens a new range of processing, which also opens the door to new jobs. An aggregate can easily be added later, keeping the initial cost of the CNC machine lower, without compromising the capability and flexibility for the future.

Christian Vollmers is the president of HOMAG Canada Inc. He can be reached at Christian.Vollmers@ homag-canada.ca or visit the website at www.homag-canada.ca