There is a saying that nothing is certain but death and taxes. I would like to add a third - we can be certain the cost of energy will continue to go up.

In the past, people didn’t worry much about energy costs, but that has changed and today it makes up a substantial portion of operating costs. There are many reasons to save energy. It is ‘green’ and ‘green’ is a great marketing tool. Consumers demand more and more ‘green’ products and the company that can claim its products are ‘green’ has an advantage over the competition. Secondly it is good to know that the environmental footprint we are creating is as small as possible. Last but not least saving energy helps you reduce your operation costs, which in turn increases profits.

The two main energy sources used in manufacturing are electricity and gas (oil). While electricity is mainly used for lighting and to drive machines, gas (oil) is used primarily for heating (the workshop, water, oil for a press or e.g. a kiln).

Warm air leaving the building means a loss of energy. Especially in the woodworking industry, where the dust collection system is constantly extracting warm air from the production area, this is a significant heat-loss factor. To avoid this loss of thousands of cubic feet of warm air every hour, your dust extraction system has to be equipped with a warm air return system. Large overhead doors, where finished products or raw materials are brought in or out can also be the reason for significant loss of warm air and thus energy. An automatic, high-speed sliding door will minimize the open time of the door. Another unnecessary loss of energy lies in the physics of warm air. Warm air rises and collects under the roof, while cold air accumulates at ground level. To keep the warm air from rising, many plants install fans to push the warm air down. A modern fan system has the potential to reduce plant-heating costs by up to 30%.

When we talk about saving electricity, the first thing that comes to mind is to turn off the lights. But with today’s energy saving light bulbs only a very small portion of energy is consumed for illumination of your workspace, and as a consequence the saving potential is very limited. There are in fact hundreds of other areas where you can save electrical energy. I would like to describe four of the main areas.

Your dust extraction system is not only important for a clean work environment, but it will improve product quality and prolong the life of your tools and machines. But if the dust extraction, the tools and the machines are not designed to effectively channel the dust flow, a lot of energy is wasted by creating more airflow to make up for the design shortcomings. Reductions of up to 40% are possible in this area.

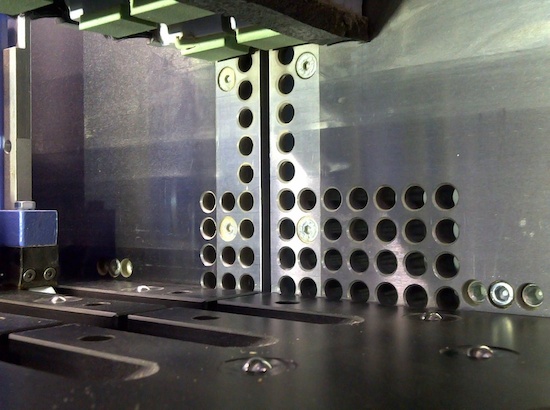

Photo shows the dust flow optimized cutting line of a beam saw.)

2.) In every production environment there are idle periods in which the machine is on, but not actually running. In many small shops and large plants machines keep running. An advanced machine control brings the machine automatically into energy-saving mode when it's not needed. Unnecessary drives will stop, e.g. the air blower at a saw, the dust extraction will be closed, the temperature of a glue pot will be lowered, or motors which are still spinning, even if nothing is there to process, will be stopped. Alternatively the operator can send the machine into hibernation by just pressing a “Green Button” on the machine. By pressing the button again, the machine will ‘wake up.’ This technology has been standard in the computer industry for years, but it is just now starting to take hold in ours.

3.) Compressed air is undoubtedly the most expensive form of energy you are using in your shop. Using an efficient compressor and maintaining your pipe system is therefore a good start. However, to actually reduce the amount of compressed air required, your machine has to be designed to consume as little of this valuable energy as possible. Are the hoses in your machine routed as short and efficient as possible, and are the valves and pneumatic cylinders efficient and state of the art? Are the cleaning intervals with compressed air computer controlled and as short as possible? Once again there are potential energy savings of up to 40%.

4.) Using the right size and type of motor, saves you money. A motor bigger than necessary is neither an advantage nor a power reserve. It just means that you will encounter more wear and tear due to the higher mass of the motor drive, which in turn creates more stress, higher abrasion, and also a higher energy demand.

The productivity of a machine also has a big impact on your energy consumption. If your machine can process the same job in two thirds of the time, the energy used to execute the job will be significantly lower, as will be labour costs.

When you buy a new car you are certain to ask for the fuel consumption, even if you only have a short commute. Your machines run many hours every day, in some cases more than 100 hours per week. The energy consumed over the lifetime of a machine is becoming an important factor to con- sider when considering a new machine.

As I said at the beginning, energy cost will keep increasing, but if you prepare yourself, your savings will too!

If you want to learn more about energy savings and to see detailed calculations of how much money you can save, send me an e-mail at Christian.Vollmers@Homag-Canada.ca

Christian Vollmers is the president of HOMAG Canada Inc. He can be reached at Christian. Vollmers@homag-canada.ca or visit the website at www.homag-canada.ca