The emergence of quick change CNC spindles for shapers and tenoners has made interchanging tooling between machines more realistic. It is critical to understand design and balancing considerations before attempting to interchange tooling between any machinery, and especially important when considering higher RPM CNC machinery.

Whenever possible, it is recommended to design separate tooling for shapers and CNC routers, as tool limitations are usually different and interchanging tooling between machines does create a larger margin of error. However, there are situations where interchangeability is possible if proper design and safety considerations are made. Using the same tooling on both machines can provide a critical level of production versatility which can reduce tooling cost and increase efficiency if planned properly.

For example, most entry door manufacturers have switched to using CNC routers to machine components, which has proven to be the most efficient and accurate option. However, there are occasions when a small batch of doors can be made more efficiently on a shaper, due to programming considerations. In this case, it would be logical to have tooling that can be moved from a CNC router to a shaper.

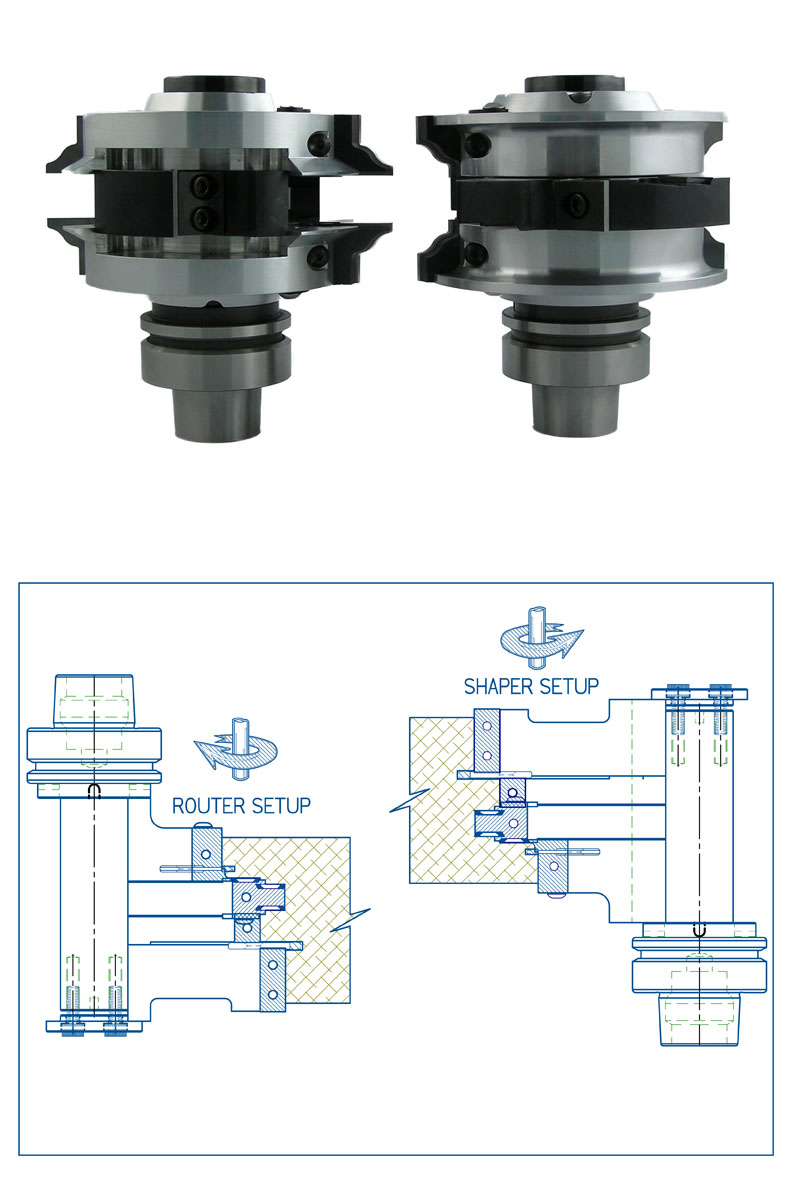

Image 1 — shows an example of an entry door tooling stack which can be interchanged between machines with HSK63F connection interface which is very common on CNC routers and new shaper models. This tooling solution utilizes light weight aluminum bodies to reduce mass so tooling can be moved from a CNC shaper to CNC router seamlessly.

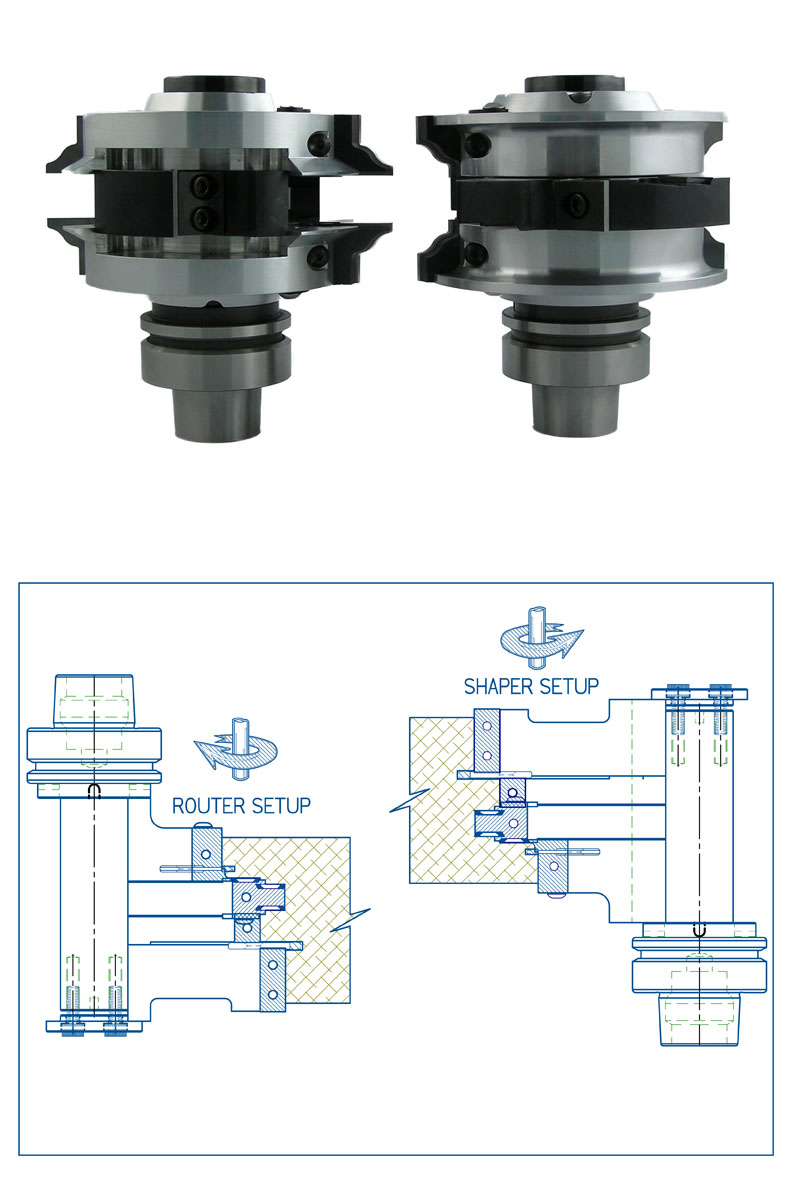

Image 2 — shows a tooling stack designed for machining window components. This is another example of a situation where tooling could be easily run on a CNC router or shaper depending on production requirements. The image shows the tooling stack in two orientations for both machines, but the application and wood profile must be able to be inverted and machined in two orientations.

Important considerations

Important considerations Weight restrictions

Depending on make and model of equipment, weight restrictions will vary based on size of machine and spindle constraints. Traditionally shapers will handle much heavier tooling to be run at lower RPM, but larger CNC routers do have the capability to run larger diameter tooling, which should be made with aluminum bodes to reduce mass and excessive forces on the spindle.

Diameter and length of tool

Size of tooling is directly related to weight restrictions of the spindle, so this should be considered in the tooling design process. Tooling must be large enough to reach required projections on a shaper, but small enough to meet maximum diameter restrictions of CNC routers. Depending on depth of profile requirements, it can be difficult to find a suitable diameter to suit both machines, so it is best to provide detailed wood dimensions, before deciding on the proper machine to make components. Many profiles can be done on both CNC routers and shapers, but some profiles over two inches depth can be difficult.

Machine Parameters

Shapers are designed to run at a lower RPM than CNC routers, so we must consider this reality when deciding on machine parameters. For example, the tooling shown in Image 1 can run at a maximum of 12000 RPM, but it will not run that fast on a shaper. This set of entry door tools can be programed to run at 10000 RPM on the CNC Router and 6000 RPM on a shaper, but the feed rate must be adjusted accordingly. Machine programmers should decide on an optimal chipload and then make adjustments according. This will provide equal cut quality on both machines, and ensure safe operations of tooling on both machines. It will also increase tool longevity, as tooling will not be exposed to excess heat caused by improper chiploads.

Tool Balancing

It is important to inform your tooling and machine manufacturer of your intentions before tooling is manufactured, so that critical design decisions can be made to ensure safe operations of tooling on all machinery. Tool balancing is a critical process which considers tool mass, diameter and other factors which can affect tool performance at higher RPM and feed rates. Most advanced tooling manufactures have capabilities to balance tooling to G2.5 spec or higher for operation at higher RPM, but it is very important that tooling is checked before deciding to interchange between machinery.

Important Note

It is not recommended to interchange tooling from a shaper to CNC router without an HSK spindle. It is possible to disassemble tooling stacks and re-assemble on HSK arbors to run on a CNC router. However, it is strongly recommended that tooling is balanced to G2.5 specs at an accredited balancing facility to ensure tooling and arbor are balanced for safe operation.

Tooling interchangeability can reduce machine down time, improve efficiency, and reduce tooling costs in many operations, if proper measures are taken to design and operate tooling properly. New advances in machine technology and tooling design have certainly made interchangeability more realistic, but safety guidelines and tool maintenance recommendations most be followed.

Consult your machine and tooling manufacturers to ensure all tooling and machine considerations are made before planning to interchange tooling between machines.