Photos: Van Arbour Design & Woodworking

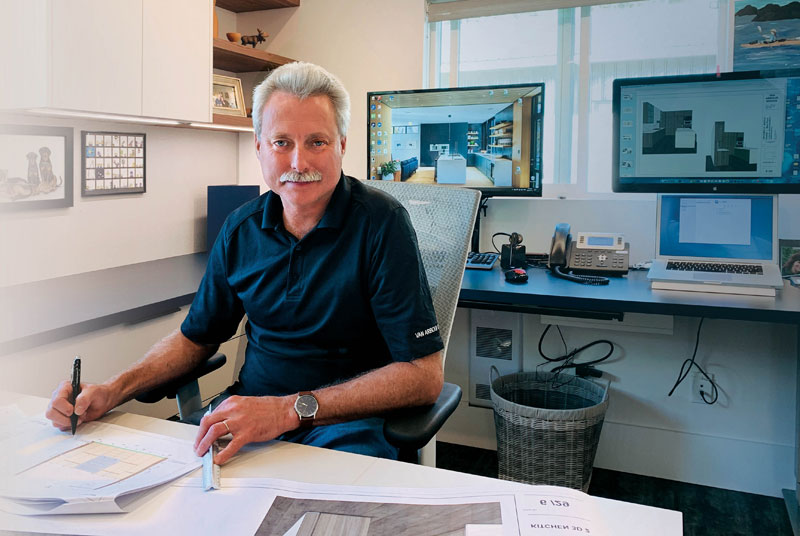

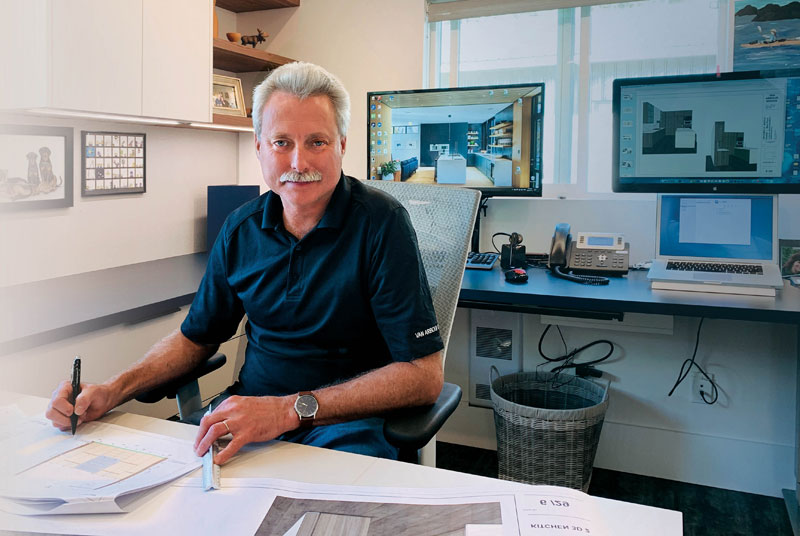

Gerald Van Woudenberg has always had an interest in woodworking and he

followed his dream.Gerald Van Woudenberg says he’s always had an interest in woodworking - from a very

young age - and he simply

followed his dream to turn it into a reality.

Born and raised in B.C.’s lower mainland, Van Woudenberg grew up on the family

farm and by the time his father asked him

if he wanted to take over the farm, he

had already decided he wanted to be a woodworker/cabinetmaker instead.

“I grew up on the farm and half of the family was working there and the other half of my father’s family was working in construction,” he says.

“I was always interested in furniture and cabinetry, but I was going to a private school that didn’t have a woodworking program, so at age 16, I decided to transfer to a school with a woodworking program.” Van Woudenberg says.

“Yes, I know that’s unusual, but I was very motivated. I guess I caught the bug from my grandfather who did some cabinetry work

and I just liked it, I watched him and hung around him and I guess it stuck.”

“Being a farmer, my dad had the ugliest

and most rudimentary tools you can imagine, but that didn’t stop me.

“I can remember trying to make stuff out of scrap wood and I think I almost burned through the only jigsaw blade he had, it was that bad.

“I didn’t know what good tools were because we didn’t have any, but I’ve always been interested in woodworking, I just loved it.”

When he was 17, his parents were building a new home and his father asked the cabinetmaker who got the contract for all the woodwork in the house if he minded if Gerald job-shadowed him, which he agreed to.

“So I worked with him on and off, after school and weekends and he was very influential in getting me into the trade.”

After high school Van Woudenberg went to BCIT (British Columbia Institute of Technology) and took an apprenticeship program specializing in bench work and joinery.

“It was a new program and he was the

first to graduate and he set a record doing

it because it was a self-paced program and

“I just blasted through it.”

The economy was really bad at the time, but he found work with a number of different cabinet shops in Abbotsford and got experience working in different shops, as an installer and in customer service before he decide to start his own company - G Van Woudenberg Cabinets - in 1986.

After 10 years in business, he changed the name to Van Arbour Design.

Van Woudenberg said when he started out he had no work lined up, so the first thing he did was cold calling.

“I made sample doors and cabinets to show people what I could do and then I just started knocking on doors.”

His first shop was in a garage on his dad’s property, “you know like a lot of good cabinet shops get their start,” he says with a laugh.

“It was a single-bay garage, I had a table saw, I had an edge sander, I had hand tools, sanders, routers, drills and that’s how I got started.”

Of course it was terrifying because suddenly, there was no guarantee of a paycheque, but he did it anyway, “because that’s what I really wanted to do.”

He started with spec homes in Walnut Grove, which is in Langley and then others in Surrey and grew the business from there. Kitchens were a lot simpler in those days and they were also just making the transition to European frameless cabinets, which are a lot easier to manage for a single operator.

“I hooked up with several contractors in the area and built relationships with them and that’s how I got my start.”

Trust and referralsVan Woudenberg says he has built his business over the last 34 years entirely on client relationships and the referrals that come from them.

His goal has always been to create cabinetry and offer design services that will reflect people’s vision for their homes.

He says clients know they can trust Van Arbour Design and count on them to deliver what they promise and on time.

Van Arbour Design creates custom cabinetry that reflects their client’s vision and style for the kitchen, bath, and other areas of their home and everything they do is done with integrity and transparency.

And he says what sets Van Arbour Design apart is its team of talented and dedicated people.

Each of the staff is detail oriented and takes pride in their workmanship and many have been part of the Van Arbour family for many years.

As far as his first shop is concerned, Van Woudenberg says he was fortunate in that the garage was actually in a five-bay building and he kept taking over bay after bay until it was all shop.

Then, when he outgrew it after 10 years, he moved to a space in Aldergrove, “just a couple of miles away from where we are now,” and another 10 years after that they purchased the property that’s still home today.

Photos: Van Arbour Design & Woodworking

Work on the business, not just in itBut it was after that first move when Van Woudenberg learned a first important lesson. That’s when his accountant took him aside and gave him a bit of a “wake up call when he told me that I was loosing money and I had to do something about it “real quick.”

He said as a result of that conversation, he began a journey to recalibrate and rework the entire business model from the ground up.

“It felt like having to start over, but it was the best thing I ever

did,” he says.

Van Woudenberg says if there is any advice he can give to anyone it would be ‘to surround themselves with people smarter than yourself, admit that you don’t know everything, always watch your bottom line and always be open to change.

“I never want to hear ‘that’s not how we do it,’ never say never.”

“I was also very fortunate in that I had met a couple of contractors, older gentlemen, and they cared enough about what I was doing to give me some advice and mentor me. One of them told me about a couple of books I should read. One was Michael Gerber’s The E-Myth Revisited: Why Most Small Businesses Don’t Work and What to Do About it.

“That really opened my eyes. Gerber talks about the difference in being a technician, being really good at what you do and being an entrepreneur, a business owner. Those are two completely different skill sets.

“One you probably have in spades, the other you probably have to develop and that was very true for me. Wearing the owner’s hat is completely different than building cabinets,” he says.

“I learned that the problem is that you are so busy building cabinets that you are not paying enough attention to the business side. You have to know your costs, your expenses and what to charge for your services and you just can’t afford not to pay attention to that,” he says.

“For me the core of the problem was pricing and knowing exactly how long it took to make stuff. Time is money and it’s the most expensive commodity, not the materials that we use, so I had to do better at tracking time.

“It’s also incredibly important to be able to look at the company and separate it from yourself. It’s just a company and it needs to be assessed and improved.”

Another decision that has worked for him was hiring a business coach.

“Even after years of being in business, I still had lots I could learn,” Van Woudenberg says.

“Everyone has blind spots, but you don’t necessarily realize it so it’s a good idea to be open to have someone who can look over your shoulder and offer advice.

“You can’t possibly know everything and if you can’t admit that you are on the road to failure. There is nothing wrong with being humble and prepared to learn. You need to be open-minded and ready to accept change,” he says.

He has also recently hired a retired accountant who is doing a forensic audit of his books from the last five years to help him mine data.

“I was never trained as an accountant and I wanted someone to come and work with me and give me a different perspective.

What can you learn from the data and how can you use it to improve your business? That’s what I’m after.”

He says the biggest thing for him was that as a small business owner, you could feel very alone. So when you have someone like a business coach help you look behind the curtain and you start looking at it from their perspective, it’s almost like having someone walking beside you, you are no longer alone and they can help you break it down into bite-sized chunks so it’s easier to deal with.

“The best way to describe it is if you’re in the forest all you see is the trees, but having a business coach takes you and lifts you out of the forest up above the trees and then you can see the forest for what it is,” Van Woudenberg says.

“It’s a new perspective and you can decide what to focus on. It takes you away from the micro and lets you see the macro. A good coach doesn’t have to have all the answers, but they need to be able to help you find them.

“As I said before, I think it’s really important to always be open to learn something new and to be willing to take advice and be prepared to work on your business.”

Photos: Van Arbour Design & Woodworking

Van Woudenberg is a board member of the Canadian Kitchen Cabinet Association and hosted a shop tour during February’s CKCA Regional meeting.

Measure everything and never

stop learningVan Woudenberg says another challenge is “that we are not building the same thing over and over – in that case you’d know your time and costs. But with us everything is custom and there are always new issues and problems.”

He says time tracking is incredibly important, both on the normal stuff, but also on the specialty stuff because that’s where things can go off the rails very quickly.

“You may think, oh, that’s only going to take me five hours. But will it, are you sure? And once you track it you find out that it took 15 hours.

“I wish I could tell you differently, but it’s still true today. This high-end specialty stuff is still tricky. If the house isn’t level, plumb or square – and they never are – then you have to install in that environment, but you have to make it look perfect and that’s never easy or quick.

Van Woudenberg says early on he was pricing per linear foot, but it turned out that really didn’t work for him. If you are a big company and have your costs figured out exactly, it might work, “but smaller companies in our industry and for custom work especially, that’s a good way to lose money.”

And even with all his experience, Van Woudenberg says he still has

to constantly tweak and make changes because material costs change and hardware changes. Designers and architects are also always pushing the design envelope so you have to stay on top of it.

It is also important to be prepared to walk away from a job.

He says there is a lot of incompetence in the industry when it comes to pricing and there have been numerous times when he found out about competitors’ prices that left him shaking his head.

“Sure, they would lose money on the job, but perhaps more importantly, it’s tough because you’re left looking expensive,” he says. “But that’s

where honesty and transparency

come in. In essence you are building

a relationship, they have to trust

that your price, even though it’s

higher, is taking into consideration

all of the things that perhaps the

other guy isn’t considering.

“We’ve had it where we were the highest price, but we got the jobs because the clients said they trusted us and knew that we knew what we are doing.”

Van Arbour Design has never advertised and all business comes from referrals, which tells you everything you need to know about building a brand based on trust and transparency.

And it starts with minding the small things. Use quality materials and deliver what you promise,

Van Woudenberg says.

“I think for anyone reading the article, I really want them to know not to buy cheap hardware or cheap materials. I can’t stress enough how important that is,” he says.

“At one of my first jobs where I dealt with customer complaints and service calls, the thing that caused the most problems was defective and cheap hardware. If you spend a little more you wouldn’t have those callbacks.

“I once had a salesman trying to sell me a cheaper line of hardware and I said no, I’m not interested. And when he asked why not, I told him that I couldn’t afford to use cheap hardware, because if it breaks I have to send someone to fix it and that costs way more money than buying quality in the first place.

The reality is, the customer doesn’t remember the great install or how beautiful their kitchen is if it doesn’t last. They’re just going to remember that it broke.”

Van Woudenberg says good news travels slowly, bad news travels like wildfire and your good name is a whole lot more valuable than an extra dollar in your pocket.

He says they also use ¾ inch plywood core, not particle board and full, ¾ inch backs, because it’s a better product and if the customer “wants to change the faces in a few years, they can easily do that and leave the boxes in place.

“Sometimes that is a tough sell, because it means the price is a little higher and most people don’t care or don’t know enough about the construction to appreciate it, but to us it is important to build a quality product. It has value and once we explain that to people they value and appreciate it. Again, it’s about building a relationship.”

Building a strong teamVan Woudenberg also believes in hiring people for character and attitude rather than ability and then “train them ourselves.”

He says finding good people is always a big challenge in this industry “and as an industry and as a community we have to take the bull by the horns and drive the process.

“People ask how do I find a good installer? Well, you have to either poach them from someone else or commit to train them yourself. That takes time and costs money and it is a challenge, but I think you have to commit to that because they (particularly installers) are the face of your company and the people your customers will interact with most, aside from your sales staff.”

Today, Van Arbour Design operates from an 8,000 sq. ft. shop and has

14 full-time employees, one part

time and one sub-contracted installer.

And even though these days he hardly ever gets a chance “to get on the tools,” Van Woudenberg, who also serves as a board member of the Canadian Kitchen Cabinet Association, still loves what he does and wouldn’t have it any other way.

He admits he misses the hands-on work because it is so satisfying and addictive, but he enjoys what he is doing now.

“Sure, my time is now spent managing and running the business,” he says, “but it is still highly satisfying because you are building something and you are seeing people’s dreams come true.

“You are creating something beautiful that will add value to people’s homes and their lives.”