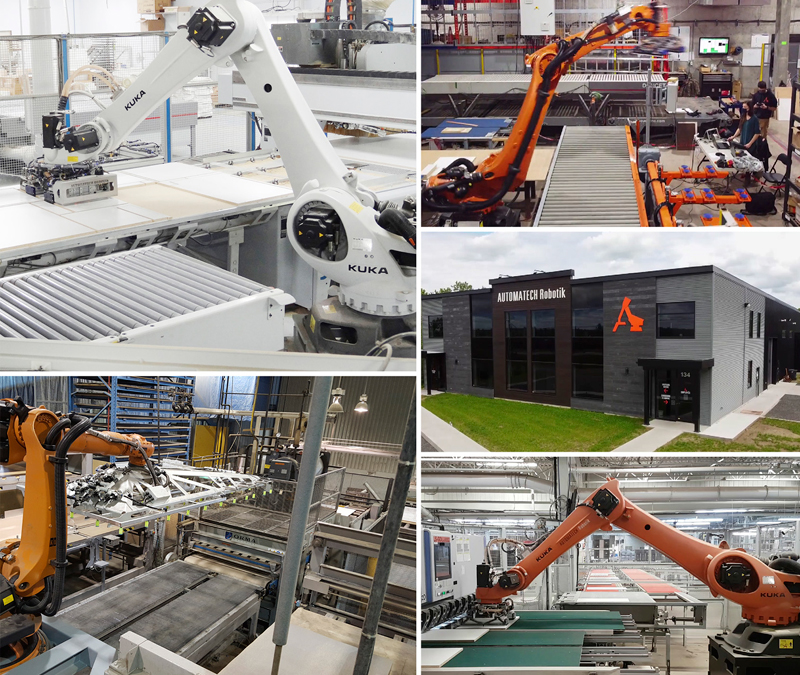

Photo: Woodworking

Tommy Gagnon, centre, speaks with members of the Canadian Kitchen Cabinet Association during a plant tour.

Woodworking spoke with Tommy Gagnon, CEO of AutomaTech Robotik, a Canadian system integrator based in Quebec, about how robotics have and continue to revolutionize the industryWhen people today talk about modern production, that often means digitalization, automation and artificial intelligence. But nearly as often they talk about robots and how they will change

our working world.

Throughout history, people have continually invented things to make their lives easier. The desire for an extra hand or some form of mechanical help to assist with heavy and repetitive tasks, is probably as old as mankind itself. Even Aristotle, the first bona fide scientist and renowned philosopher who lived in ancient Greece, thought of automatically operating machines. Aristotle had the idea of machines that simplify and automate tasks,

but it took more than 2,000 years before the world was ready.

Thinking of today’s typical articulated robots, we can’t get past the names George Devol and Joseph Engelberger who presented the prototype of the Unimate in 1959: Weighing one ton, hydraulically operated and programmed via a magnetic drum, the world’s first industrial robot could perform around 200 operations. It did so well that starting in 1961, it was used in production at General Motors. Initially for handling tasks involving heavy, hot metal parts, and from 1966 also for welding

and painting. That really was the start of robotics in industry.

The furniture industry has been slow in adapting robots in its manufacturing processes. The use of robotics in this industry is still relatively low compared to other industries, but the possibilities are compelling.

Industrial robots are on the verge of revolutionizing furniture manufacturing, because they are getting more versatile, faster and less expensive.

Robotics will also play an increasingly important role in timber construction in the coming years. Robots will not simply replace craftsmen, but rather co-operate with them.

In the woodworking industry the integration of robotics continues to gain momentum: Regardless of whether it’s material handling in conjunction with sawing, laminating, processing edges, drilling, routing, assembling, packaging, or sorting and picking — robots can be used in batch size 1 as well as mass production. Innovative feed and stacking systems or pick-and-place applications ensure high performance with maximum accuracy and extraordinary precision.

Last November, AutomaTech Robotik and KUKA, a German manufacturer and one of the world’s leading suppliers of robotics, extended their long-standing partnership to include the entire North American woodworking market.

AutomaTech Robotik, and Stiles Machinery (HOMAG) signed a strategic partnership to integrate HOMAG CNC equipment with proven advancements in robotic part handling using KUKA robots.

Also, Biesse recently announced their collaboration with AutomaTech Robotik that combines Biesse machinery with advanced robotic parts handling. The partnership signals a new era of enhanced productivity for forward-thinking customers intent on growth and excellence.

Woodworking explored this theme in conversation with Tommy Gagnon of AutomaTech Robotik. Their technology implementations support workforce maximization and production refinements. We asked what this means for the future of the industry and which companies are using these powerful and versatile new tools that range from single robotic cells to fully customized robotic production lines.

Photo: Woodworking

AutomaTech Robotik is a solution provider that supports North American woodworking companies by providing the most effective and agile wood-transformation automation.

We customize our solutions to the customer’s needs so they can achieve sustainable growth without changing everything in their factory. We have been a technology leader for more than a decade. Now, with the help of our partners, Biesse and HOMAG/Stiles, we are ready to bring our solutions to ambitious wood manufacturing leaders who want to become more efficient.

What can robotics accomplish in the woodworking industry?More than you would imagine.

People always think about simple tasks such as handling, but the robots have so much more potential than that. Industrial robots can do much more complex tasks such as sanding, painting, cutting, factory management by consolidation, as well as more integrated tasks related to the digital technologies.

The most important question is: ‘What is the best solution for my company?’ The easy answer: ‘Look for your bottleneck’.

Like I’ve said many times: ‘We went to the moon with a less powerful computer than our actual smartphone.’

Now, in a time of labour shortages, the answer is far more complex, needs a strategic vision and a clear development plan.

A customer told me once, you are not in the automation business, you are in the HR business. I think he was right on the spot.

In summary, this is the easy answer. Robotics are a solution to the labour shortage so many companies experience.

What are the main benefits of adding a robot to your workforce?There are a lot of benefits to having a robot in your company, but the most important one we tend to prioritize here at AutomaTech is not the first one that usually comes to mind.

The best thing a robot could do for you is, wait for it: Reliability.

Reliability has the following definition: the quality of being trustworthy or of performing consistently well. Robots are exactly that.

They can now do complex tasks the same way with the same precision for the entire shift, without asking questions, taking breaks, calling in sick or developing skeletal muscular problems due to inefficient ergonomic tasks. This quality gives your workforce the chance to focus their efforts on real human tasks, to maximize the efficiency of your factory.

In addition, being a machine gives robots the advantage of being interconnected to the entire factory: They can collect the data and measure the yields.

Why is this advantageous for manufacturers using robots? Because it makes it possible to improve certain processes and to identify where the bottlenecks are in production. When you add all those lost seconds together, it is often thousands of dollars in lost productivity.

That is obviously only the tip of the iceberg of what robotics can do for you, but in short, the automation we offer here at AutomaTech Robotik makes it possible to move towards a more profitable factory, in a market where labour resources tend to be increasingly scarce.

What applications are you seeing

the highest demand for?Machine tending is clearly leading the way.

This is not a one size fits all solution. It really depends on the value stream mapping of the company.

What is the investment range?You can find a lot of different robot solutions from $100,000 to multi-million-dollar projects. Typically, a woodworking robotic project will cost between $200,000 to $500,000. The real question is what do you need?

The most important thing is not the price, it is knowing what you need.

Do you see a higher demand for robot technology? Where?Yes. The actual state of the industry with its persistent workforce shortage in North America, and the thirst for knowledge of the next generation has significantly increased the demand on automation in the last five years.

Recent significant advances in technology and artificial intelligence have raised questions about the role of workers in an era where robots and algorithms are increasingly able to perform many job duties, including those previously believed to be non-automatable.

The COVID-19 pandemic has also added to those concerns, as businesses have turned to new automation technology to perform a broader range of tasks traditionally done by humans.

Automation is really the production way of the future and the companies that do not take this turn will find it difficult to be competitive in the future.

Will the role of human workers change in the future workforce?Rather than asking the operator to move parts manually and change CNC programs, automation now opens the way to allow employees to do more interesting and less exhausting tasks in your factory than what they were used to.

The result is a much happier workforce that will want to stay in your business for the long run.

Contrary to popular belief, a robot has a very positive impact on the life of every employee in a factory. The goal of automation was never to replace humans, but to make life easier and free up time to focus on what is really important.

Automation has created more interesting jobs that are now more centred on developing and improving the factory with ideas, do maintenance on the equipment and quality control.

Photos: Contributed

The most important thing about robotics and automation, is not what it can do. The real question is: ‘What is the best solution for my company?’ The easy answer: ‘Look for your bottleneck.’

Customer commentsYves Allard, Project Manager at Matthews Aurora™ Funeral Solutions, a provider to the funeral home industry:

“The strength of robotic is that you can build a parametric program. Each new part is as simple as adding a new line in an excel sheet giving it a new item number and the dimensions. The program behind the scenes will do all the math. That makes a project pay for itself the first time and can pay for itself again by the time you have a new idea and you modify your parameters.”

Luke Elias, Owner, Muskoka Cabinet Company, a provider of residential and commercial cabinetry:

“The biggest benefit for a robotic is less material handling, more consistency, faster operation and faster cycle time. Implementing robotics in manufacturing is definitely the way to go in the future. It makes the operation so much more efficient and competitive”.

Simon Gagnon, Senior Manager, Teknion Corporation, a company that designs, manufactures, and markets office systems and related office furniture products:

“The benefit of a robotic cell is not only labour benefit since we don’t need anybody to adjust manually the high-pressure laminate on the particle boards but also from a raw material point of view. But the major element with a robot is that it could be reprogrammed or readjusted to the new reality of our business which is changing, as all businesses are changing. This is like a long-term investment that is always up to date”.

Pascal Herbert, Plant Manager, Columbia Forest Products, a manufacturer of quality, decorative hardwood plywood and veneers for homes and commercial settings:

“The machine for which we had a project was a laminating press, a continuous machine. The problem we had was a new contract where we had to stack the panels according to the grade and the defects. The equipment we had was not able to do so. We decided to use robots on our project because the budget was 20% less than a mechanical version of a similar project. Also, the maintenance cost for a robot

is a lot smaller compared to

regular mechanization.”

Keven Houde, General Manager, Concept Caskets, a company specialized in the designing and fabrication of wooden caskets:

“We decided to automate a long time ago to compete with low-cost countries. Plus, the quality is always the same since a robot will do the same process all the time. The two largest benefits about automation and robotics are that we are able to keep our production costs as low as possible to be competitive and to maintain consistent quality because a robot does the same process all the time.”

Bastien Larouche, Owner Ro-Bois-Tic, a manufacturer of custom cabinets:

“The biggest benefit of robotic is that we make sure we are aligned with the customer demand: fast, accurate and at the best price possible.”