The factory is equipped with state-of-the art-equipment and the orders are still not getting shipped on time. Order fulfillment is still a daily struggle. The quick reasoning I most-often hear is that we do not have sufficient capacity, we need more machines, more overtime and more people.

That could be the case, but more often it is not

Certainly, if you are getting orders out on time, we can all agree we have the right capacity. If you constantly push more orders onto the shop floor and are falling further and further behind, well then, most likely, we do not have sufficient capacity.

Most often, I see companies struggling and not getting 10-20 per cent of their order volume out in time. They are not falling further behind, but they are not catching up either. So, in the big picture, they are producing the right amount of volume, but somehow, they are not producing the right things to complete orders.

This is typically not a capacity issue and extra people, and extra machines will help, but it is not the solution. The problem is most often a scheduling and organizational problem.

In previous articles I have written about fit and complete, the biggest timewaster of them all. You need to get some control of that first. Once this is at a reasonable level, scheduling, the manufacturing model and organization become more important.

There are sophisticated software packages on the market helping manufacturers to navigate in the maze of scheduling options. The fact that I am personally not in favour of traditional scheduling packages does not mean they don’t work. I find them to be too complex and I have practically given up on them. I am however convinced, that the different and newer Manufacturing Execution Software (MES) developed and more tailored to our industry, will allow us to do better scheduling.

The challenge I see in the industry is that often only very basic scheduling is in place. The plant is loaded with daily/weekly target volume (sales dollars, cabinet count…) and then it is up to the shop floor to get the orders through the factory. This is a classic push system.

This works reasonably well if the factory has much more capacity (no bottleneck) and/or the bottleneck is the first operation. If the bottleneck is further down the production process, the upstream processes are overproducing and all the extra WIP is blocking the flow and impeding the bottleneck further.

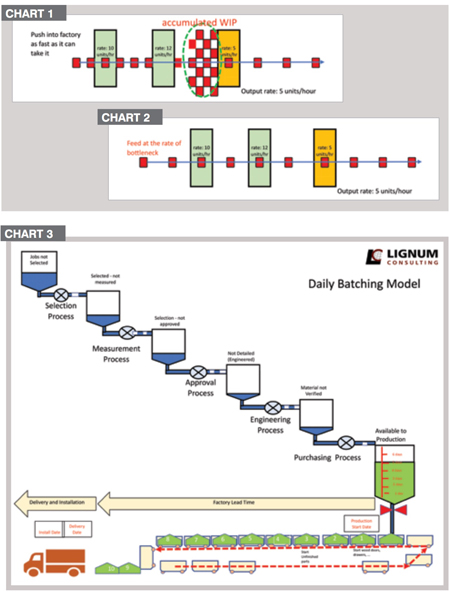

Identify the bottleneckYou want to create flow, and a bottleneck is restricting the flow. Chart 1 shows a schematic of what happens when the flow is throttled. An obvious sign of a bottleneck is that material accumulates in front of the bottleneck and there is little material after the bottleneck. These workstations are starving for work.

If you feed the plant at the rate the bottleneck can process, you regain flow (Chart2).

Protect the bottleneckUsually, you treat all workstations equally with attention and resources, except the bottleneck. The bottleneck needs to be kept open. Almost any effort is warranted when it comes to the bottleneck. For example, if you have multiple machine breakdowns the bottleneck machine needs to be repaired first. When you know what the bottleneck is, you have an advantage. You just need to monitor and improve the bottleneck and the other steps in the value chain will fall into place. Once the bottleneck operation has been widened/eliminated, another operation will become the constraint/bottleneck and needs to be treated as such.

How to protect the bottleneck?If a person from a bottleneck operation does not show up for work you need to transfer someone from another area, even when it means breaking up a productive team. All non-bottleneck operations need to keep the bottleneck operation running at its optimum. Your cross-training program needs to support this goal.

You might even accept a lower productivity rate at the bottleneck station. For example, if that team works with four persons and a fifth person will only provide 5-10 per cent more output, it might be justifiable. (25 per cent more labour cost for 5-10 per cent more output) If you look at the one workstation, it does not compute, however if this is within a 50-person operation the calculation is different (1 person added to bottleneck operation (1/50 = 2 per cent more labour results in 5-10 per cent more output).

Sequencing the ordersEach operation step has an optimum sequence. Following this sequence improves the productivity on this operation. For example, the edgebander would like to run all the same thicknesses together and within the thickness all the same edgebanding. However, if you need to sort all material after each operation you might hold up production. Again, protect the bottleneck. The sequence in which the bottleneck needs the material/WIP trumps all other preferred sequences, even if it slows down other operations marginally. Optimize the overall, not the detail.

Put your controls at the bottleneck If you put measurements on each operation and expect high volume output, you incentivize and promote overproduction therefore you should focus on overall output. As the overall output is limited by the bottleneck, practical and detailed performance measures should be established and monitored there.

In the same way major highways meter the on-ramp during rush hours, in a similar way, we need to feed the plant what they can handle (again see Chart 2).

Daily batching Let’s take daily batching as a starting point. Over time this should migrate to much smaller batching. Daily batching is too big of a batch in the long run, but if you have not established your ordering rhythms it is a good start. Once you feel comfortable, I would recommend moving to a day batch (or if you have shift work, a shift). Once you master that, you reduce the work order bucket to a shift. This would mean the size of the work order will give the first operation two hours of work. Before that time has elapsed, the next bucket of orders will be issued. When you reach that level of excellence, the production flow is no longer interrupted by rush orders. Any rush request by a customer is just added/substituted into the next batch. It no longer makes a difference to production.

Chart 3 shows a schematic on how scheduling can systematically fill buckets of work orders for production (daily buckets).

The order fulfillment process starts way earlier than the manufacturing process. Each order must go through many processes before production starts. If pre-production is the overall bottleneck, then your improvement initiatives have to focus there. In that case, improving the machining capabilities has limited benefits.

Best results will be achieved when the buffer (green silo) ahead of the production cycle has a few days of orders available for production. If you have only one day of production in the buffer, the scheduler has no option but to release them. She/he has no means of optimizing. If the scheduler however has a few days of available orders, the buckets can be filled in a way to optimize production. The scheduler can balance the work

for production.

Where do you start?The main reason why we hold on to big batch sizes is because we think we need them. Most companies already have the equipment to run smaller batches. The smaller the batches, the faster an order flows to the factory. The shorter the factory throughput time, the longer we can leave the orders in the pre-production buffer (green silo). It does not mean, we have shorter factory lead-time so we have longer time to complete the paperwork/engineering for an order! We need to create this buffer to give the scheduler options. These options utilize the manufacturing resources more efficiently and increase capacity.

In traditional manufacturing engineering/industrial engineering we analyse every operation on how fast we can do it. The faster the better! This is one important point we need to rethink.

We need to focus on how fast we can have an order through the factory. This means you measure from the first cut on the first piece of that order until you completed and packaged the last cabinet of that order. With this thinking and focus, reducing batch sizes becomes a natural direction.

Most companies are still working on weekly batches in the pre-production processes. This needs to be reviewed as well. Start on 1/2 week batches and see how much faster you get on the front end.

As you improve your scheduling you utilize your available resources, become more productive and more predictable.