As 5 axis CNC technology has decreased in price and gained in popularity, aggregates are losing relevance and practical purpose in some applications. However, after a closer look at specific aggregate options, it becomes apparent that there are many aggregate options that can perform critical operations that cannot be done easily with a 5 axis CNC machine. Aggregate manufacturers have pivoted, to focus on product development and innovation of concepts for new applications, to optimize machine performance. There is still a huge market segment of new, and existing 3 axis machines that can benefit from aggregate technology.

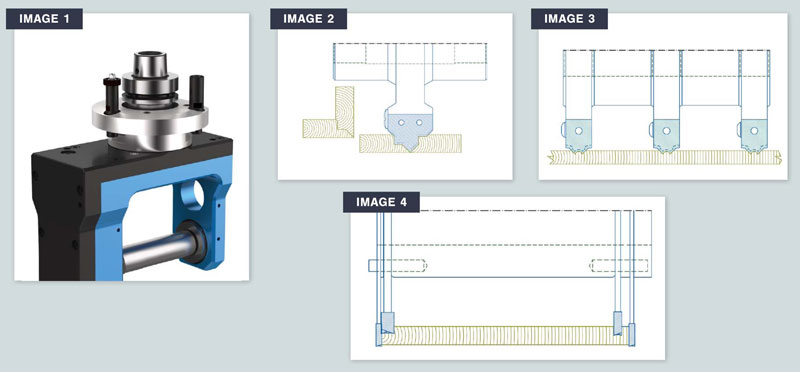

Image 1 shows a good example of a popular aggregate concept that can be used on 3 axis machines to provide substantial production benefits and overall cost reduction, by optimizing the machining process.

The moulder aggregate

This aggregate functions exactly like a traditional moulder with a spindle supported on both ends to provide optimal rigidity and balance for larger tool bodies. The unit is available in spindle lengths of 100 mm, 120 mm and 170 mm to allow for maximum width of profile. This rigid design and versatile set up can turn your 3 axis CNC router into a moulding machine capable of performing critical operations that were previously impossible. As long as your CNC is equipped with C axis capabilities, there is a wide variety of options to improve flexibility and efficiency of CNC Routers. Aggregate specific tooling solutions are manufactured by several precision tool manufacturers on a custom and stock inventory basis.

ADVANTAGES:

Cut quality

Machining v point profiles has always been a challenge with traditional router bit formats, as the point of the tool has minimal clearance and tends to produce a chatter mark at the tip of tool due to the obvious lack of rim speed. In contrast, the tool shown in image 2 is rotating from the top orientation of the material and will have superior tool geometry to provide better finish quality and overall final product.

Production efficiency

The usable length of the arbor is the key feature which allows tooling to be stacked with spacers to machine multiple profiles in one operation to improve efficiency.

Image 4 shows a blade assembly that can machine all grooves and perimeter cuts in one single pass. This operation would normally involve small diameter router bits running at low feed rates in four separate passes. In some cases the groove widths are too small for router bits, so blades from above may be the only option to achieve success.

Accuracy

Lock mitre profiles shown in image 2 are manufactured much faster in a single pass with cutter head above material, but these critical cuts can also be done with greater accuracy and consistency compared to a router bit format. It is advantageous to machine profiles from top orientation for greater profile options. For example, image 3 shows a bead profile that is very common in paneling and door products. This exact profile is not achievable with a router bit, as the orientation for the router tool will not allow sharp corners at the bottom of profile or the radius to be located beside an angle. These are obviously minor details; however, when the finished product is displayed, these minor details can create a dramatically different effect.

Flexibility

Product versatility is a primary benefit that leads to increased production efficiency. The ability to stack tooling assemblies on one arbor in a variety of set ups make the options endless. Furthermore, the simple fact that the aggregates can be run multiple passes over an eight or 10 foot panels makes moulder aggregates more versatile than traditional moulders which commonly have a 12 inch maximum width capacity.

CHALLENGES:

Weight

It is very common for purchasers of this product to attempt to use existing Steel Body heads from a moulder or shaper. This is NOT a good idea, as most steel heads will exceed the weight restrictions of the aggregate and machine spindle, which can create serious safety and performance concerns. Consult the aggregate manufacturers to determine exact weight restrictions and communicate effectively with your tooling manufacturers to ensure the final tooling solution is designed safely.

If steel bodes are necessary, creative tool designs using secondary milling to reduce the weight of steel is sometimes an option. But in most scenarios, aluminum tooling and spacers are the only way to ensure safety. All of the tooling solutions shown in the images can be made from lightweight aluminum to work within the weight restrictions of the machine and aggregates. Tool balance accuracy is critically important, and balance reports must be provided from your tooling manufacturer before integration of aggregate and tooling.

Size

These units are obviously larger in size that any other tool or aggregate commonly installed on CNC routers. It is important to discuss this issue with your machine manufacturer before purchasing a unit. Adequate clearances on the tool holding unit of the machine is critical, but also the range of movement when the aggregate rotates. Aggregate manufacturers have extensive product knowledge but also have a good understanding of a wide variety of CNC machine configurations, so communication with your aggregated supplier is critical to success.

APPLICATIONS:

Curved moulding

The moulders aggregate’s most common use has traditionally been for curved moulding components in MDF or solid wood. There are many videos online reflecting the various solutions that can be produced with greater speed and accuracy.

Kerfing

This is a term used to describe multiple blades stacked in close proximity to remove material for the purpose of bending. Kerfing is commonly done on traditional through feed moulders, but the aggregate option can be more attractive in many cases if the material is wider that 12 inches.

V-grooving/folding

Anyone producing folded products with veneers or various other skin material, understands the importance of accuracy at the tip of the tool. Router tool formats are still very commonly used on 3 axis CNC machines to produce folded joints, however, the superior tip geometry of a cutting tool being run from above makes the moulder aggregate a far superior option to produce accurate results

Lock-mitre

This profile shown in image 2 is very similar to standard V –grooving, with the added benefit of profile which improves stability of the joinery, and allows for easier final assembly. The ability to stack two tools on one arbour and run in one single pass makes this concept extremely efficient and produces the absolute best final result. This type of set up is particularly beneficial in post or column construction, where long liner tool paths are required.

Beading & shallow profiling

Image 3 shows a variety of shallow profiles that are very common in panel and door products. These profiles can be challenging and in some cases impossible with a router bit. But the moulder aggregate produces these profiles with the absolute best cut quality possible. Furthermore, it dramatically reduces cycle time on a product that is traditionally very low margin on the sales end, but extremely time consuming to produce without the proper equipment. This particular design allows tool locations to be moved horizontally on the spindle so that spacing can be changed for ultimate flexibility.

CONCLUSION:

The need for machine efficiency has never been greater as we strive to reduce cycle times and reduce machining cost. Aggregate tooling, which can be added to any CNC machine with C axis, removes many of the limitations associated with CNC Routing. The enormous range of aggregate tools that are available today will open many new doors and allow manufacturing companies to diversify their product range, improve quality and reduce pricing. For a very reasonable investment, the appropriate aggregate can improve your operational efficiency.