Operational excellence does not begin on the shop floor. It begins in the boardroom - with a clear understanding of your company’s overall business strategy.

Too often, our industry rushes to implement isolated solutions: Investing in automation, reorganizing workflows, or adopting new software - without first stepping back to ask a critical question: What are we actually trying to achieve as a business?

When we don’t start with strategy, we risk locking ourselves into narrow fixes that may solve the wrong problem. For example, a shop might optimize production speed, but ignore bottlenecks in engineering or chronic gaps in customer communication. Or it might invest in equipment that increases output without increasing sales capacity to match.

Alignment is the key!

Before we improve anything, we must understand:

What is our value proposition?

Who is our customer, and what do they truly value?

Where do we want to grow - or defend - our business?

By grounding operational decisions in strategy, we ensure that every improvement supports the bigger picture. That’s how operational excellence becomes a driver of competitive advantage, not just internal efficiency.

What do we mean by operational excellence?

Operational excellence means a company must perform well overall, not just in one department, in order to be considered excellent.

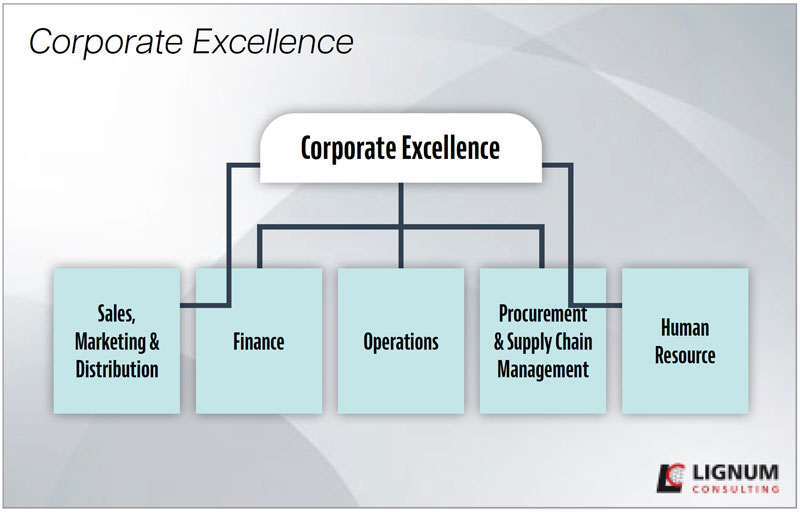

First, let’s place operational excellence in a bigger picture. Operations do not stand alone. They are embedded in overall company performance. Operational excellence is a part of corporate excellence or business excellence. The company’s performance becomes excellent when all the elements perform well and in alignment.

In this article, I will focus on operations, but for context, I will also briefly touch on the other key areas.

Sales, marketing & distribution

This includes product development, branding, corporate identity, market intelligence, sales organization, distribution, and marketing.

Finance

In addition to the classic areas, this includes product costing and pricing. Financial planning and controls affect all areas of the company. While it’s outside my direct expertise, I recognize how important it is and how much has been written on the subject.

Procurement & supply chain management

With about 40 per cent of revenue typically spent by purchasing, this department is often the company’s biggest spender. Placing orders, receiving goods, and managing inventory are just the basics.

High performance starts when a company builds reliable, long-term supplier partnerships aligned with company goals. Balancing cost pressure with strategic make-versus-buy decisions requires strong cooperation between finance and operations.

Human resources

Many companies claim, “people are our greatest asset,” but too often this is just a slogan. If you mean it, you need a clear and focused approach. HR is about far more than payroll—it’s about developing, supporting, and retaining your team.

Operations

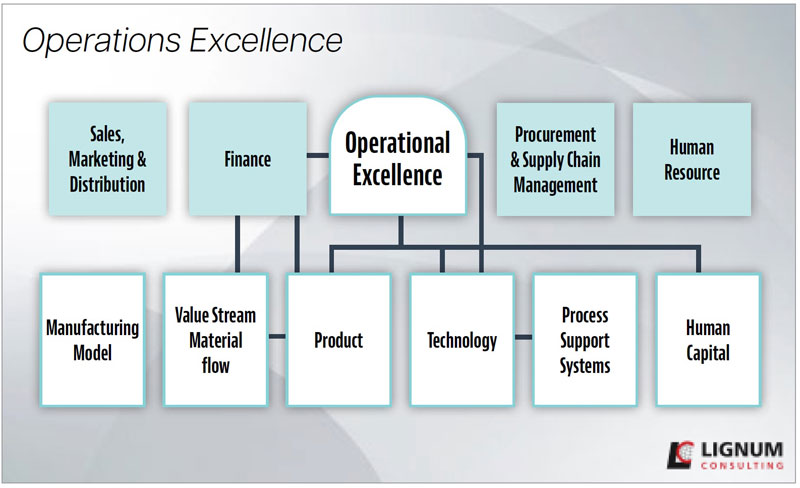

When we focus on operational excellence, we can divide it into several sub-categories:

Manufacturing model

How is your production organized, scheduled, and controlled?Are you producing into finished goods stock based on forecasts, or building to individual customer orders?

Do you manage your floor with Kanban systems, order-based manufacturing, or WIP inventory?

Choosing the right model affects:

Capital requirements

Manufacturing lead time

Space needs

Inventory levels (WIP, FG, RM)

Productivity

Flexibility

Value stream

The value stream covers all material and information flows from the first to the last customer contact. It includes layout, machine alignment, material handling, and buffers.

Improving the value stream impacts:

Material flow

Space usage

Lead time

Machine utilization

Labour productivity (direct & indirect)

Inventory levels

Product / product engineering

Your product should match customer needs and manufacturing capabilities. Standardizing materials and design details makes the product easier and cheaper to build.

Optimizing the product impacts:

Setup time

Capital investment

Material variety

Inventory

Productivity

Complexity of data

Total process time

Technology

This covers all production tools - machines, jigs, fixtures, devices, and tooling. Balance is key. Don’t invest in top-tier machining if your assembly is still manual. Being good begins when your technology is balanced across the full process.

Technology affects:

Capital cost

Labour productivity

Product quality

Flexibility

Capacity

Process complexity

Process support systems

This includes your ERP, MRP, MES, QA programs, Lean initiatives, maintenance planning, and key performance indicators (KPIs). It’s not just the software - it’s how the systems support your team.

Support systems influence:

Lead time

Ease of doing business

Indirect labor cost

Flexibility

Inventory

Speed to market

Human capital

Organizing, training, and motivating your workforce is a major part of operational success. With skilled labor shortages, this is more important than ever.

Investing in people affects:

Productivity

Labour cost

Staff retention

Acceptance of change

Speed of implementation

Equipment utilization

Cost of quality

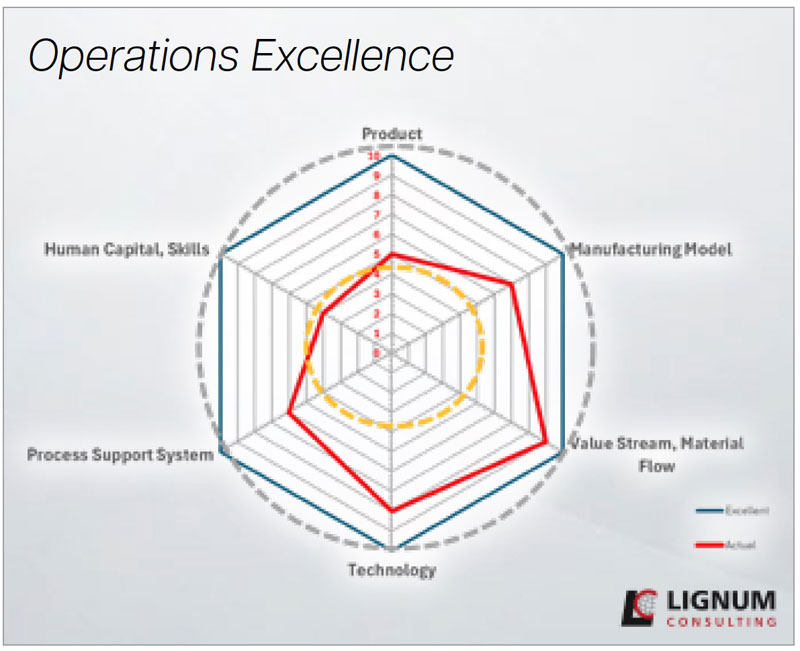

Alignment Is the keyword

Each element above affects overall performance. But success depends not only on how well each one performs, but how well they all work together. Performance is not the sum of each part, it is limited by the weakest link.

Sometimes, strong performance in one area can compensate for another. But more often, misalignment drags down the whole system. For example, a factory built for standardized production won’t succeed if Sales pushes highly customized products.

Even minor misalignments add up, especially against competitors who have everything working in sync.

Misalignment can be fatal

Imagine a company with state-of-the-art machines, but outdated training, or an unclear product strategy. The factory won’t perform. Excellence is only possible when every part of the system is aligned to a shared goal.

Next step: Focus on the right problem

Operations teams often dig deep into technical details. That’s important. But not every detail needs optimization. It’s about optimizing the whole system, like winning a game with a team, not just individual star players.

The first step is to identify where misalignment exists. For example: If sales and operations are not aligned, which one should change? That decision must fit the company’s overall strategy.

You don’t always pick the easy fix, you pick the right one.

Score your performance

You don’t need a scientific study to start. For small and medium-sized businesses, a combination of management insight and trusted supplier input can reveal a lot. You’ll be surprised how often your team and suppliers score performance areas the same way.

Double down, don’t slow down

If you’re ahead in one area—don’t slow down. Keep pushing forward there. But put extra focus on areas where you score low. Balance is what creates excellence.