Photo: Woodworking

Ferruccio Corrente came to Canada from Italy in 1964, at age 16, to pursue a better life and opportunities.

Once in Canada, he immediately started working as a cabinetmaker and quickly moved on from being a general labourer while also attending school at night.

Corrente then worked for store fixture companies where he met a lot of great designers from around the world and when that company was getting ready to close he decided to start his own company - and never looked back.

That was in 1983 and he called the company Unique Store Fixtures.

Quality has always been number one for Ferruccio. It is in fact the foundation upon which he built his business. Since its founding in 1983, the company has been producing award-winning luxury retail and residential interior fixtures, everything from displays, custom millwork and metal.

And through his pursuit of excellence - both in design and craftsmanship – and following the motto that ‘’if it is not good enough for him, it’s not good enough for his customers,” he has continued to grow the company and racked up an impressive client list. Among them are some of the world’s leading companies such as Tiffany & Co, Gucci, Burberry, Saks Fifth Avenue, Rolex, Tim Hortons, Bergdorf Goodman and Holt Renfrew. And that work in turn has resulted in many prestigious industry awards.

Corrente says he had been doing a lot of work for some bigger brands, like for example Tim Hortons, so he knew a lot of people and when he set out on his own they gave him a chance to continue to do work for them.

And, when he did start Unique Store Fixtures, “a lot of the good, good people who worked with him at his previous job, came to work with me at my new company.

“It was easy to work with those guys,” Corrente says, “because we knew each other and we were all very good at our craft.”

All in the family

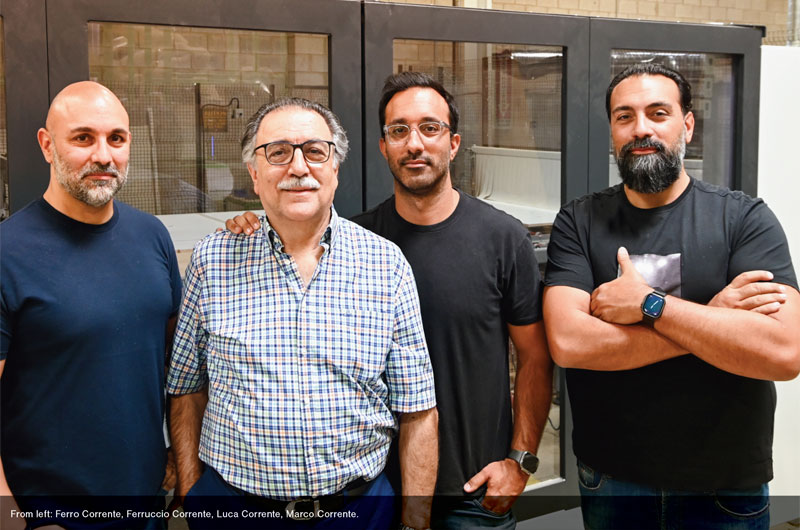

Over time, all of his sons - Ferro, Marco and Luca, who are all managing partners with different responsibilities - joined him in the business to truly make it a family affair.

They all grew up in the business and then set out to get their education and experience other jobs, but eventually returned to the family business.

And while Ferruccio is still the boss who overseas everything, the sons each have their own responsibilities and departments they look after.

Luca is handling mainly IT and equipment. Marco looks after project management, sales and customer management, and Ferro runs production and looks after the shop floor.

Pivot

With decades of experience and the aforementioned commitment to quality, Unique is a leading millwork services company respected across North America, but a few years ago they’ve decided to pivot the business towards more residential work.

Corrente had previously built the odd kitchen, but the main focus had always been store fixtures.

Their pivot towards the residential market came in about 2018, as a hedge against what was happening in the retail market, Luca says.

“Online has impacted the retail market and the days of retailers spending most of their money in stores are gone. It’s still a strong market of course, but we wanted to diversify the business to stay ahead of the curve,” he says.

And they’ve also added hospitality and restaurants.

And while they still do high-end store fixtures, today their market is predominantly residential.

Which is also why they recently rebranded from Unique Store Fixtures to Fabbrica Unique.

Their customers are mainly in Ontario, but they also sell into the U.S. and are planning to grow that portion of the business and perhaps even set up some manufacturing there to serve that market.

The complete package

Lucca says a lot of their production is for builders and designers, single and multi residential, high and low rise and everything in between. They have completed condo buildings that are hundreds of units. And there is a lot of custom work, from mid market custom all the way to high-end with three to four million dollar millwork packages.

“We are a little bit different in that we offer them a full turnkey solution. We offer packages for entire condos, but also common areas and receptions. And we are doing the complete package, millwork, stone, metal and glass, whatever the project requires. Even the countertops.

So it’s everything from top to bottom.

This ability to deliver turnkey solution is the result of Corrente deciding years ago that he wanted to be able to do more than wood.

So that also sets the company apart, the fact that they are not limited to wood, but work with all kinds of different materials, anything from metal and stone and upholstery.

Ferruccio Corrente says he decided early on to open his own metal shop “and we later added stone as well, so we were able to manufacture everything in house, which really expanded our expertise and efficiency.

“That’s what kept us going; the fact that we could do everything in house meant we never had to wait for anyone else to cut a piece of glass for us, so we could meet all the deadlines because we controlled everything in the process, the complete project,” he says.

“And our expertise and multi-material manufacturing capability sets us apart to this day. Everything is done in house.

As a result, Fabbrica Unique has been able to complete packages.

Automation

The company occupies some 70,000 sq. ft – they combined two buildings – at its Vaughan location and employs around 60 people. Most of that space, around 62,000 sq. ft., is shop area.

They have also invested heavily in automation to give them an edge over the competition.

That and the fact that they can manufacture everything in house, has kept them at the top of the industry. For example, just a few years ago, they did 4,300 menu boards for Tim Hortons drive-throughs because they were able to do them, complete with metal work, in house.

“We made the decision in 2019 to revamp our IT system and by that I mean we built it from scratch,” Luca says.

“We created our very own custom IT system for RFID and labeling to on-the-floor automated processes such as robotics. It took us about a year and we started implementing that in 2020 and only then did we buy the machinery we needed.”

So that’s the opposite of how many other shops do it. Often, companies buy new equipment and then integrate it into their processes. But for Unique this was the way to do it. Get the system ironed out before changing production over and then struggle to work out any kinks.

“We realize anyone can buy a CNC,” says Luca, “but it’s the systems behind that that make the difference. And we brought the best equipment and we did it in steps as we continued to produce for our clients.”

As a result of that automation and technology, they build a kitchen, the boxes, from start to finish and only one guy ever really touches a part until it gets to assembly.

“But then we also have many other processes that are quite labour intensive, which is why, despite our level of automation, we still have 60 employees, Luca says.

“Take metal work, that’s quite labour intensive as is some of the custom millwork we offer, which involves a lot of manual, detail work.

“What we found is we want to remain flexible.

We are not just a kitchen company, or a store fixture or a millwork company, we are a full-service ‘manufactory.’ That’s an old term, but we chose it because it describes exactly what we do.

“We have been working with Biesse for our automation,” Luca says. “We made that commitment to them early and they have been great to work with. And we are currently working with them once again - I actually have a phone call with them tomorrow - on a fully-automated, 24-coil edgebanding solution that would be our final piece to have the entire process fully automated from start to finish so no one is touching the parts anymore. So that would make it a true, true batch size 1 and just in time.”

Other technology supporting the craftsmanship at Fabbrica Unique includes Kawasaki Robotics and Edge Automation. We welcomed our business partners Kawasaki Robotics and Edge Automation to showcase how advanced technology is shaping the future of production. With the seamless integration of the CabSort system, the company has also streamlining material handling, reducing downtime, and increasing efficiency - all while staying true to the craftsmanship that defines them.

“Our success is based on our great employees and even though we’ve automated a lot, we have never laid anybody off because of that,” Luca says.

“So whenever we automated anther part of the shop, it was an adjunct, never a replacement for people’s jobs.

We have many employees who have been here for a long, long time and it’s their expertise and craftsmanship that gives us an edge over the competition.

“Quality and craftsmanship are number one and always have been.”

They also have a dealer line of cabinets sold exclusively through a dealer network of about 300 across Canada, but mainly Ontario. Cabineteq offers “the most valuable products: all locally manufactured, and imbued with Italian inspired design.”