Tammy Vanderstarren is the operations manager at Timmerman Woodworks in New Lowell, Ontario and she said applying for and landing a job there “was one of the best decision I ever made in my life.”

Vanderstarren previously worked for a general contractor in the GTA (Greater Toronto Area), but during the pandemic she decided to get out of the city and live and work in a more rural area.

“It’s funny, when I was looking for a new job, Timmerman kept appearing in front of me,” she says. “On my LinkedIn and in recommendations from friends and the more I looked into what they were doing and mass timber, I knew this would be a great fit. It really sparked something in me and I wanted to be a part of that so I applied and was fortunate enough to land the job.

“It really was one of the best decisions I’ve ever made. I really feel like I lucked in on this opportunity, it’s a phenomenal organization and Mike and Henry (Krans), who founded the company in 1999, are the kindest and best bosses that you can find, they are genuinely great people, and that translates down to the entire company.

Asked to describe what the company does, Vanderstarren says, “Timmermann Timberworks is a mass timber design built construction company, meaning we will take anything form a napkin sketch to pre-engineered plans and adjust them to mass timber if required and then we follow that through the life cycle of the product, from fabrication, sourcing material, delivering to site and the complete installation.

And to my knowledge, SilvaSpan, our second company, is the only company that mass produces NLT in North America and we are patent pending on our process.

More than two decades of craftsmanship

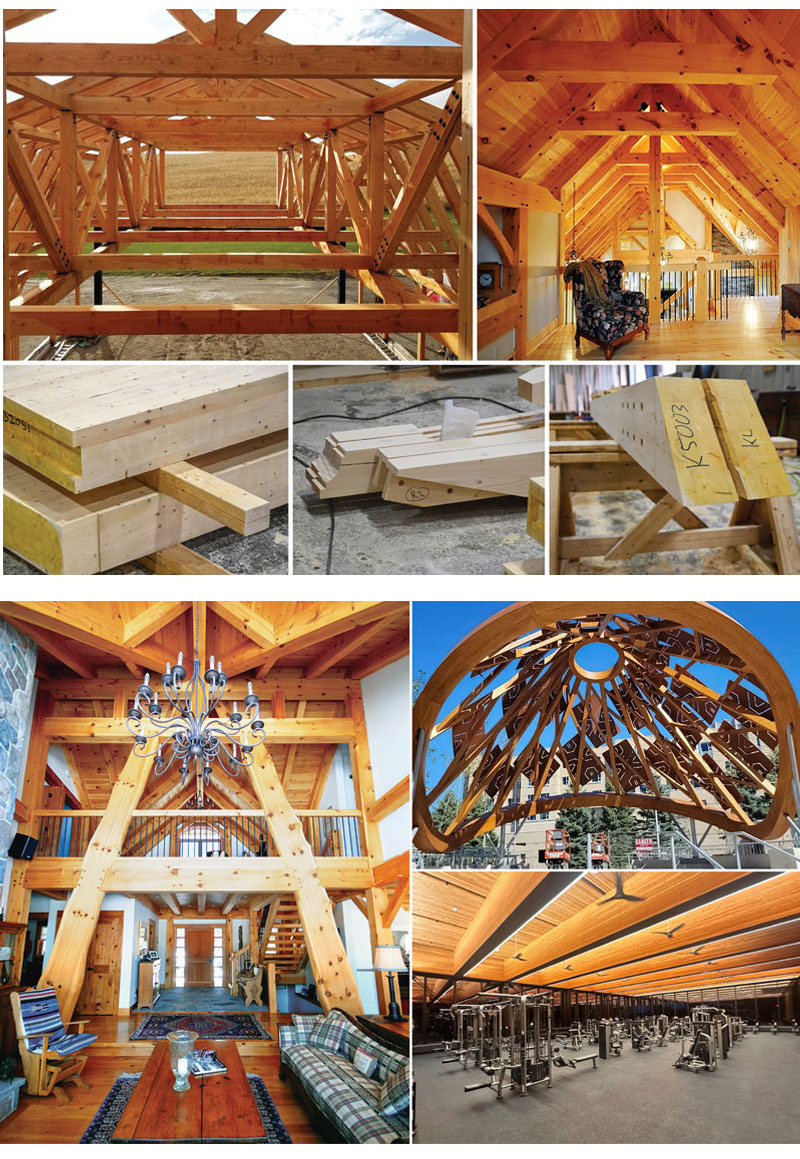

There are very few companies anywhere that can draw on the same broad palette of materials that wood offers and the technical experience Timmerman provides. Since its founding, they have grown and adapted navigating the growth and popularity of the mass timber industry by taking on large-scale commercial work while maintaining their roots in residential timber framing.

Timmerman is essentially a custom carpentry with a team offering a diverse skill set. The company offers traditional timber frame joinery, crafting mortises and tenons in the time-honoured manner. That means everything is cut by hand carefully put together. Having perfect joinery plays a significant role in having a timber frame that will stand up to the test of time for generations.

“I think what makes Timmermann as unique as it is, is that we are all very excited about what we are doing,” she says. “There is a real pride in the work and – given the growth of mass timber – it’s exciting to have all these opportunities in the market place. It makes for a great place to work if everyone is as excited and positive as you are, the opportunities are endless.”

Timmerman has grown over the years to expand its services to include custom mass timber fabrication, design development and installation and establishing Canadian mass timber leader SilvaSpan using a proprietary manufacturing process that mass-produces precision-engineered, nail-laminated timber (NLT) panels with finger-jointed lumber. SilvaSpan’s NLT panels provide fully coated protection, structural integrity, architectural beauty, long spans and up to 100 per cent waste-diverted wood - benefits impossible to achieve with other mass timber solutions.

“SilvaSpan was born when we were awarded a project in Toronto that used NLT,” Vanderstarren says. “In order to build that project, we developed a prototype NLT press. It was a six-story building and we knew we couldn’t built that by hand so we had to find a solution to automate and speed up the process and we did.”

Mass timber popularity

Mass timber use across the country is exploding and for a good reason. The advantages of mass timber construction are manifold.

“Architects will look at the aesthetic appeal, mass timber also typically offers a much quicker installation on site compared to traditional construction, mass timber has basophilic design attributes (the innate human tendency to connect with nature and life forms), its structural integrity matches steel and concrete and then there is of course the fact that it is a greener, more sustainable way to build because of carbon sequestration,” Vanderstarren says.

“And, mass timber is more cost effective for most projects.”

Vanderstarren says the company didn’t really start marketing its NLT product until about a year, year and a half ago, but now they are seeing some NLT in tenders. In addition, when they receive a tender “where we believe that NLT would be a better fit because of the spans required or the application of the material, we will offer NLT as an alternative.

“Ultimately, we will work with all mass timber, but as I said, if we feel our product could be beneficial in a given project, we would certainly advise the client accordingly.

Timmerman has built thousands of residential buildings and completed hundreds of commercial and institutional projects right across the country. Their smallest market is B.C., because that is a market that’s already saturated.

“We will go to B.C. if the opportunity presents itself, but we’re not going to chase that market,” Vanderstarren says.

Timmerman will look after shipping close to home, but anything else is handled though a shipping broker. Installation, however, is handled strictly by their own installation crews. Projects can take anywhere from two weeks to several months with one to two months being the average length it takes to complete a project on site.

“We work mostly with SPF (spruce, pine, fir) standard dimensional lumber, but we can bring in anything our clients want to use’ Vanderstarren says.

“We get the odd request for other woods, such as Douglas fir, which we then bring in from the West Coast, but again, it really varies depending on what the architects vision is and what the owners’ vision is for that project. At the end of the day we give them the options they want. So we will deliver whatever the clients request, but as far as our default is concerned, it’s SPF. And all of our dimensional lumber is sourced from Canadian mills.

“At this point it is all softwood, but we are also looking at bringing in hardwoods,” Vanderstarren says.”

As far as the future is concerned, Timmerman will continue the work to secure its position “as an industry leader in timber framing, providing superior service, craftsmanship, and attention to detail.”

Fact:Timmerman Timberworks was formed by brothers Henry & Michael Krans who combined their building experience and the desire to produce superior quality timber frames. Starting out in a small old barn in Simcoe County Ontario, the brothers took on many significant projects and steadily grew in the coming years and started hiring several employees, many of whom are still with them today. Today the company has about 60 people on staff total; that includes shop and office staff as well as installation crews.