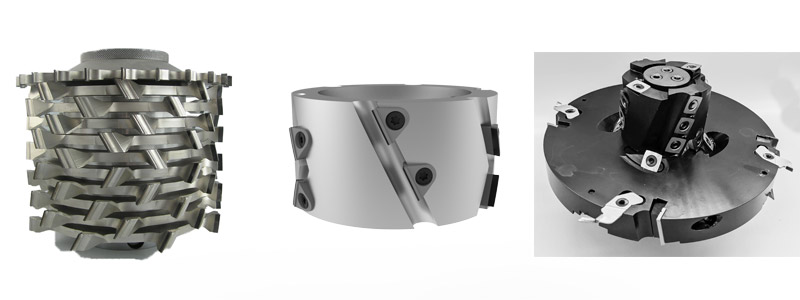

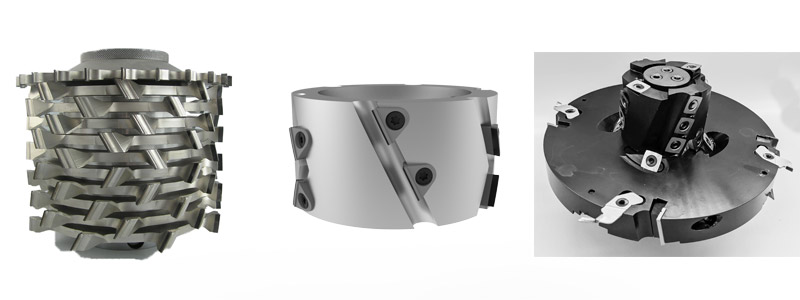

Images 1, 2 and 3.

Images 1, 2 and 3.Polycrystalline diamond cutting tools (PCD) have increased in popularity over the last 25 years and become the preferred option for high volume machining of most materials in the wood industry.

Tooling designs have evolved to improve cut quality and cutting-edge longevity in a wide variety of applications and materials. PCD tools have traditionally been manufactured in brazed diamond format with the diamond material adhered permanently to a steel tool body. In recent years, a variety of cutting tool manufacturers began making PCD tools in an indexable format using replacement inserts, to improve flexibility and convenience in specific applications.

Traditional brazed diamond tooling Image 1 shows a brazed diamond cutter head, which remains the most common diamond tool design with PCD adhered to a steel tool body. This design is extremely precise and accurate, but there is a requirement to send the tool back to the manufacturer for sharpening or retipping.

New replaceable diamond insert tooling Image 2 shows a polycrystalline diamond insert tool (PCD), which is designed with a steel or aluminum tool body for insert installation using precision screws or gibs to hold inserts in place. This design allows for quick convenient cutting-edge replacement without a requirement to send tools back to the manufacturer.

Benefits of

PCD inserts: Quick convenient replacement of cutting edges without shipping entire tool body back to the tool manufacturer

Can be used in lightweight aluminum tool bodies if weight restrictions are a critical factor

Reduction in sharpening and retipping costs

Relatively cost effective compared to carbide

and brazed diamond in

some situations

Challenges: Slight lines can appear on surface finish between the diamond segments

Brazed diamond tools can be manufactured and maintained to a higher accuracy tolerance as PCD inserts must be seated into a tool body, which limits accuracy for new and replacement inserts

Profile limitations exist beyond straight edges and slight angles

Industries currently using PCD inserts: Panel processing Edgebander premill stations are a critical high-volume cutting operation in panel processing. PCD inserts were integrated into premill tool designs as one of the first introductions of PCD inserts to the wood industry. Brazed diamond premill designs completely replaced carbide options over time, but brazed diamond does have some limitations on specific materials. Particleboard is a very inconsistent recycled material, which tends to chip the PCD cutting edge easily, resulting in premature cutting-edge failure. Initially the only solution involved sharpening and retipped of brazed diamond tools, which increased costs and machine downtime. PCD insert tools were designed to solve these problems and allow the machine operator to quickly replace the damaged portion of the cutting edge easily on site.

Entry door manufacturing Entry door manufacturing does involve large cutting tools with long cutting edges to machine door thickness up to three inches in some cases. Due to the size of parts, linear footage counts are high and cutting tool longevity is a critical factor affecting machine efficiency. As more abrasive composite material such as fibreglass have been introduced into entry door products, diamond tooling has emerged as the preferred cutting edge alternative. Initially brazed diamond tools were very common in high volume entry door production facilities, which optimized machinery efficiency and tool performance. However, repair costs of brazed diamond tools can become prohibitive in some entry door edge operations. Brazed diamond tools perform very well on clean material, but introduction of hybrid composite material does introduce some inconsistencies, which can fracture the diamond cutting edges. Random staples or other foreign metal materials can create a necessity for urgent and costly repairs.

Due to these reasons, there has been a transition to more PCD insert designs to limit down time and costly cutting-edge replacements. The diamond inserts shown in Image 2 can be installed on larger diameter heads for use on double end tenoner or routers, to cut the complete door edge. The PCD inserts can also be oriented on a three-degree angle if the machine does not have

tilting spindles, which allows for a standard three degree bevel to be machined on the door edge.

Window and door manufacturing Image 3 shows a different format of PCD insert designed to cut a 3 mm groove. Most window designs utilize a 3 mm groove for insertion of window seal, so this groove design has become a high-volume operation in window manufacturing. All grooving operations are hard on cutting tools due the amount of heat generation created inside the groove, resulting in a dramatic decline in tool life. This problem can be exaggerated by certain wood species used in window production, which are extremely abrasive. Given all the factors having a negative effect on tool longevity, it is imperative to design a grooving system that is durable and cost effective to replace. There are some carbide insert options available, but PCD is always preferred to ensure optimal tool life and profile accuracy. Therefore, this PCD insert grooving system provides the best alternative to carbide options.

Critical considerationsAny insertable cutting edge must be installed with attention to detail and care must be taken to install inserts accurately and safely. Use a torque wrench and follow the guidelines provided by the manufacturer to ensure the screws are tightened properly. This will ensure inserts do not move during cutting operations, which will result in poor cut quantity and safety concerns.

Conclusion: If used in the proper production environment, PCD inserts can provide benefits beyond brazed diamond tool formats and optimize tool and machine performance. Cutting tool and labour cost reductions can be realized if PCD inserts are installed properly in the tool body and inventory is managed effectively. As tool designs evolve to meet the demands of modern materials and machinery, PCD Inserts will undoubtedly be used more frequently to solve future production challenges.